关注次数: 次

商品类型:Metal Polishing Machine

上架时间:2025-03-28

设备参数:Sandblasting machineSandblasting machine is a kind of equipment that uses high-speed abrasive particles to clean, remove rust

咨询电话:+8613328008563

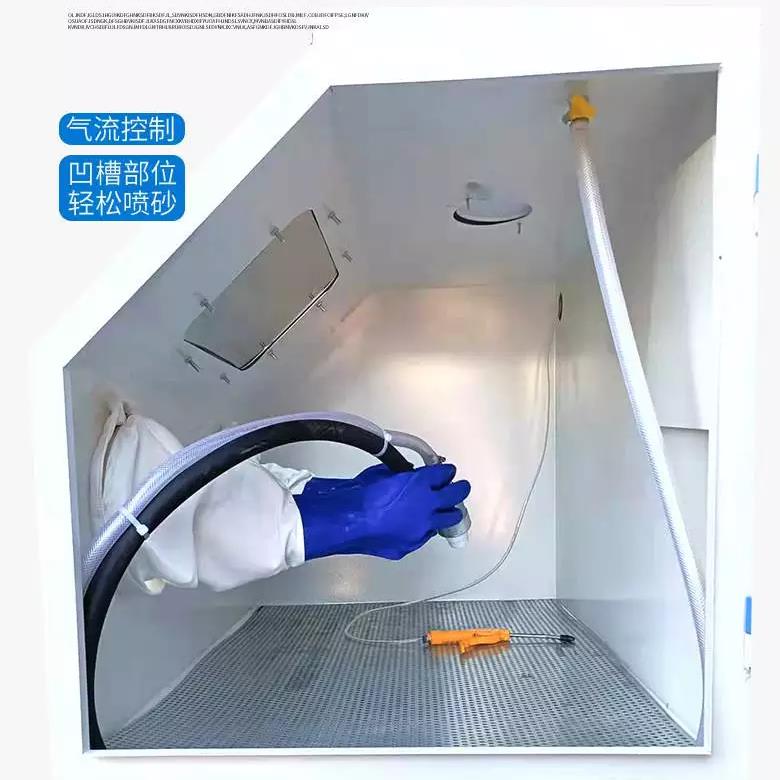

Sandblasting machine

Sandblasting machine is a kind of equipment that uses high-speed abrasive particles to clean, remove rust, remove oxide scale, increase roughness and other processes on the surface of an object. Its application range is very wide, mainly including the following aspects:

Metal pretreatment: used to remove rust, oxide scale, old paint film, etc. on the metal surface, and provide a clean surface for subsequent processes such as painting and plating.

Mold processing: used for plastic molds, die-casting molds, rubber molds, etc. to remove dirt and oxides, and improve the surface finish and service life of the mold.

Shipbuilding: used for rust removal, old paint removal on the hull, deck, cabin and other parts, as well as to improve the adhesion of the coating.

Aircraft and automobile manufacturing: used for surface treatment of aircraft and automobile parts to improve the corrosion resistance of parts and the adhesion of coatings.

Construction industry: used to clean dirt and paint on the surface of concrete, stone, bricks and tiles, etc., in preparation for repainting or decoration.

Glass surface treatment: used for frosting, engraving, ink removal, etc. on the glass surface.

Electronics industry: used for cleaning, decontamination, and oxide removal of printed circuit boards (PCBs), as well as improving the adhesion of the circuit board surface.

Art carving: used for carving and sanding the surface of artworks and sculptures to enhance the artistic effect.

Casting industry: used for deburring, descaling, and surface cleaning of castings.

Stone carving: used for carving and polishing the surface of marble, granite, and other stones.

When using a sandblasting machine, it is necessary to select the appropriate abrasive type, jet speed, and jet angle according to different materials and different processing requirements to ensure the processing effect and extend the service life of the equipment. At the same time, operators should strictly abide by the safety operating procedures and do a good job of personal protection to ensure safe production.